Water Tube Boiler

Capacity Range: 3.500 bis 50.000 kW

Energy Carrier: Superheated Steam, Saturated Steam or Hot Water

Pressure Range: up to 85 bar(1,233 psi)

Steam Temperatures: up to 520°C (970 °F)

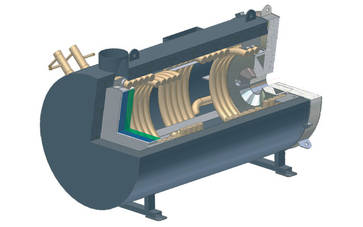

Technology: Single-drum water tube boiler providing natural circulation with radiation passes and convection heating surfaces. In water-tube boilers, the water to be evaporated is being piped through the water tubes, which also form the heating surfaces. The convection-heating surface is also made from water-carrying tubes, being heated by the flue gases.

The boiler sidewalls consist of a multiude of such water-carrying pipes, which are brought together at the respective ends in collectors forming wall surfaces. The collectors are connected to the steam drum via downpipes and riser pipes. The water-carrying pipes are called Downpipes, Riser pipes are the tubes that direct the generated saturated steam into the steam drum.

One boiler pass is formed from four sidewalls, depending on use referred to as radiation-, blank- and convection pass. Together, they form the boiler body of the water tube boiler. The pipes of the convection heating surfaces, which include the super heater, the pre-ecaporator and the economizer are grouped into bundles of tubes and installed into the convection pass. Depending on the operating parameters, our design software determines the most economical number of such water pipes, as well as the required length of pipe at a given pipe diameter.

--

Suitable for all solid fuels. Can be equipped with the various combustion types, which are being optimally integrated into the boiler. As this water pipe construction allows for an ideal design of the combustion chamber.

Pre-Chamber Smoke Tube Boiler

Capacity Range: 500 to 18,000 kW

Energy Carrier: Superheated Steam, Saturated Steam, Hot Water or Warm Water

Pressure Range: up to 36 bar ( 842 psi)

Steam Temperature: up to 450°C (970°F)

Technology: In the fire tube boiler, the flue gases are being conducted through the flue gas pipes, which form the heating surface. The water to be evaporated flows around the flue gas leading flue pipes. The arrangement of the heating surface is built directly into the water area of the boiler drum, below the evaporation surface.

The flue pipes of the heating surface are combined to tube passes. Depending on the operating parameters, our design software determines the most economical number of such flue gas pipes, as well as the required length of pipe, as well as the pipe diameter. In order to achieve the highest possible efficiency of the flue gases, we determine whether the boiler drum is to be fitted with one, two or three flue gas pipe passes, which defines the product designations as one-, two- or three-pass boiler.

The diameter of steam drum, as well as the required pressure level relates to the drum wall thickness and in turn pre-determines the boiler constructor's design possibilities. So, in order to maintain wall thicknesses offering manufacturing advantages, we define the power limits our pre-chamber smoke-tube boilers.

Pre-chamber smoke type boiler with one pass convection heating surface - steam capacity 10 t/hr. at 32 bar ( 465 psi).

--

A proven system, where the special design of the pre-chamber meets the technical combustion related requirements of even the most difficult fuels.

Thermal Oil Boiler

Capacity Range: 1,000 to 25,000 kWth

Energy Carrier: Heat (Steam, Thermal Oil, Warm Water, Hot Water) or Refrigerant

Pressure Range: up to 10 bar (145 psi)

Steam Temperature: -100°C to 450°C (212°F to 842 °F)

Technology: The heating surface of our thermal boilers is comprised of two concentrically arranged pipe cylinders, which are mounted tension-free in a gas-tight welded steel housing. In order to ensure optimal and even flow through the heater, the heat transfer oil tube segments are connected in series.

The cross-counterflow process allows for excellent heat transfer from the flue gas to the thermal oil. The flue gases flow through three passes into a flue gas collection chamber, which makes for the entire volume of the heater.

One Pass and Two Pass Flame-Tube Boiler

Capacity Range: 650 to 18.000 kW

Energy Carrier: Saturated Steam, Hot Water

Pressure Range: up to 16 bar (232 psi)

Technology: Multi-pass flame tube / smoke tube boiler, with flue gas inlet, turning- and discharge chamber. Firing over directly mounted gas/oil burner or in combination with pre-combustion for solid fuels.