Process Steam: Maximum Energy Efficiency

Process steam plants generate low-pressure or high-pressure steam for production processes. The generated steam is uesed for example for drying, heating, humidification or similar processes.

Especially in the food, pharmaceutical and paper industries as well as in breweries processes, steam is required in a precisely defined quality and quantity.

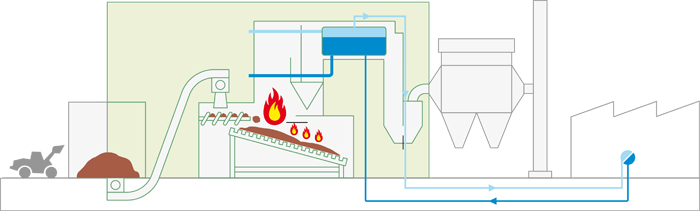

All LAMBION-Process Steam Plants consist of:

- Fuel supply and feed-in system

- Heat Geeneration Component (Furnace and Boiler, possibly Superheater)

- Flue Gas Cleaning System

- Ash Removal System

- Operation and Control Equipment

LAMBION process steam systems are available in scalable performance ranges from up to 50 MWth.

Roner AG

Biomass steam boiler system converts the residual grape marc to bio-energy without intermediate storage.

Sector: Distillery, Grappa, Fruit Brandies, Liqueurs

Fuel: Grape Marc, Aprocot Kernels, Olive Kernels

Energy Source: Saturated steam 3,2 t/h, 10 bar (145 psi)

Capacity: 2,200 kWth

CO2-Reduction potential: 6,595 t/Year

Heating Oil Savings: 1.85 Million Litres/Year

Pollmeier Massivholz GmbH & Co. KG

Biomass plant is heating the entire plant and supplies the steam and drying chambers with process energy.

Sector: Sawmill

Fuel: Production Residuals, Sawdust, Sander Dust, Bark

Energy Source: Saturated steam 12,3 t/h, 3 Bar (44 psi)

Capacity: 8,700 kWth

CO2-Reduction potential: 26,082 t/Year

Heating Oil Savings: 7.33 million Litres/Year